Hebert Foundry & Machine, a family owned and operated business since 1912; offers expertise in casting machining that is unparalleled in the machining industry. There are few foundries that perform complex machining operations and there are even fewer machine shops with adequate experience in machining complex castings. HFM is highly experienced in the machining of castings.

Our full range of services allows our clients to save time and resources by utilizing HFM’s expertise in both sand casting and casting machining. Never again will your company be caught in the middle of foundries and machine shops blaming each other while you are left with unusable, scrap parts. Scheduling is easy for purchasing personnel when there is no need to juggle the deliveries of castings to machine shops and to other operations (e.g. painting, anodizing, helicoil insertion, sub-assembly operations). HFM provides finished parts and assemblies that are ready to use. Painting, anodizing, plating, and component insertions are all scheduled at HFM.

HFM purchases castings in iron, steel, and stainless steel to machine to customer specifications. Once again, the customer is freed from scheduling multiple suppliers and is never caught in the middle of scrap warfare.

At Hebert Foundry & Machine, Inc., our staff of experts supply our clients with machined castings and assemblies that are produced to print, that are produced cost-effectively, and are delivered on-time and on-budget.

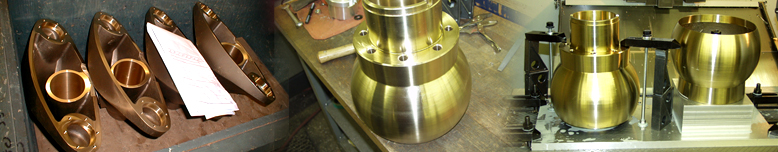

There are pictures throughout the website exhibiting un-machined castings, machined castings, painted castings, and sub-assemblies.

Casting Machining Capabilities

• bar stock up to 2 ½” diameter on a bar-feed lathe

• up to 28 inches in diameter on our CNC lathe

• vertical CNC mills

• rotary tables, high speed spindles with capabilities from 30 to 60 inches

• ability to machine tall castings

• drip feed capabilities

• complete complex dies, patterns & coreboxes

• quality assurance

Secondary Casting Machining Capabilities

• blanchard grinding

• bullard turning

• broaching

• horizontal milling

• lathe operations

• drill press/tapping lines

• radial drill press work

• MIG/TIG welding

• assembly operations

HFM has a state-of-the-art facility that includes the most modern CNC (computer numeric controlled) machinery. The CNC lathe department can accommodate bar stock up to 2½ inches in diameter on a bar-feed lathe; to 28 inches in diameter on CNC lathes with chucks and faceplates.

HFM uses vertical CNC mills that are made in the USA and are Fadal VMCs. All vertical CNC mills are equipped with rotary tables, high speed spindles, and have capacities to 30 by 60 inches. A variety of right angle heads allow for the efficient machining of ‘tall’ castings.

The capability to DNC, or drip feed, the CNC code allows Hebert Foundry & Machine, Inc. to machine complex dies, patterns, and coreboxes.

HFM’s Starrett CMM (co-ordinate measuring machine) performs both first-article and production inspection of cast and/or machined parts. As part of our quality assurance program, tooling is checked for accuracy on the CMM.

Hebert Foundry & Machine’s conventional operations include Blanchard grinding, Bullard turning, broaching, horizontal milling, lathe operations, drill press/tapping lines, radial drill press work, MIG/TIG welding, and assembly operations.